Supply chains had (are having?) their moment in the sun following the outbreak of COVID, but especially in the fallout of that initial wave. The history books will one day attribute the outbreak and ensuing shelter in place orders to a massive surge in eCommerce. Unable to shop in stores, online shopping became a necessity. Retail brands and companies across all aspects of the supply chain seized an opportunity to demonstrate the endless potential of business in the modern era. Even many skeptics found themselves convinced of technology’s ability and propensity to do good.

At that time, the onset of our current supply chain issues was perhaps not as inevitable as hindsight might suggest. If it were, there wasn’t much time to sit around thinking about it. For many DTC brands, online orders were double or triple what they’d projected on Q4, just a few months before. Those companies’ supply chains hustled what seemed would be a short burst with light at the end of the tunnel when the world reopened. Fast forward a year – the volume isn’t what it was, but any decrease in eCommerce sales was only dust clearing. What’s left is still a very different industry (and world, for that matter) than we remember from 2019.

Even if it feels less frantic now than a year ago, supply chains are still redlining by normal standards. The ports of LA and Long Beach are both byproducts and perhaps archetypes of the overarching strain on the economy. By November, global trade seemed paced more for the 19th century than 2022, and the following month, law enforcement agencies, including ICE, were warning American families of counterfeit items in Santa’s sleigh.

This brings us to today – a couple of weeks into the new year. The high-level issues remain. You know all about those if you’re in or around the industry, even peripherally, you know all about those. But some other interesting trends emerged this past year that we think are well poised to transcend the moment’s challenges and carry the industry forward in 2022. Here are the ones to follow through the next 12 months.

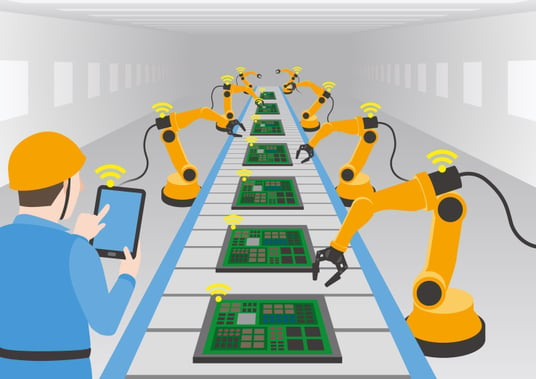

Automation

Robotics, machine learning, artificial intelligence, process mining, drones, and autonomous delivery systems are some of the buzziest tech terms of late. However, automating our working world here in the US has also been a bit of a contentious topic.

It’s ironic that the supply chain service industry has faced criticism for dated and even obsolete tech integrations. But, if we’re honest with ourselves, that isn’t an entirely unfair characterization.

And it’s also true that automation exists at various points along the supply chain in ways that increase productivity and protect human workers and their livelihoods.

And it’s also true that automation exists at various points along the supply chain in ways that increase productivity and protect human workers and their livelihoods.

Rather than replace workers, there are ways in which automated systems can free up workers to do more meaningful work. For instance, each delivery order, dock receipt, bill of lading (B/L), sea waybill must be stored and processed – a “time-consuming, manual task that inhibits businesses to reach operational excellence” according to industry analysis firm, AIMultiple.

A scenario like the above is especially wrought with the potential for human error. That is generally the case for tedium like manual inventory management (like with a pen and paper) of every SKU, truck, carrier, or container. Automating this phase of operations builds innate efficiency into a business.

Meanwhile, employees who previously spent their days tracking and recording can take on higher-order thinking tasks that only a human being can do. At the most fundamental level, workers can afford to focus more time and attention on quality control within their department, including oversight of new AI assets. These individuals could also be instrumental in planning and applying further automated solutions for inefficiencies at other operational phases.

These tasks are often carried out on pen and paper by employees in the warehouse, taking up valuable time and often leading to human error when recording and submitting information. The benefits of automation, both in and out of the warehouse, include increased efficiency – manifested by increased fill rates and decreased cycle times, as well as increased warehouse throughput time, reduced labor and operational costs, elimination of human error, and improved inventory management.

While the notion of scaled automation in the supply chain or any industry seems the stuff of science fiction even today, 2021 data tells a very different story – one that ends with increasing rates of AI adoption over the next year. In the first half of 2019, North American companies spent $869 million on almost 16,000 robots. According to the World Robotics 2021 Industrial Robots report, 3 million industrial robots were working in factories throughout the world this year, a new high and a 10% rise over the previous year. The research demonstrates new robot sales increased by 0.5 percent in 2020, with 384,000 units sold worldwide.

Blockchain

Less to say here, but that is not indicative of the potential impact of blockchain technology in the supply chain. Global expenditure on blockchain adoption across the economy is expected to exceed $11 billion in the coming year.

Less to say here, but that is not indicative of the potential impact of blockchain technology in the supply chain. Global expenditure on blockchain adoption across the economy is expected to exceed $11 billion in the coming year.

In terms of the supply chain, the technology offers a ton of potential functionality, not the least of which is transparency and traceability. For example, blockchain can use immutable, tamper-proof data to increase access to vital information like product origin.

Sustainability

A deluge of research has been published on supply chain sustainability, focusing on customers’ demands for transparency and ecologically friendly products and packaging. According to a recent poll, 83 percent of respondents believe it is “essential or very important” for companies to produce environmentally friendly products. Another study indicated that 81 percent of consumers consider transparency vital or very significant.

Long story short – more companies are deciding to make their supply chains more environmentally friendly and transparent. The trucking companies, 3PLs, and regional carriers with whom brands work along the supply chain are following suit lest they limit their ability to submit RFPs and acquire new business. Ultimately, though, we also believe that companies are working hard to increase sustainability and decrease environmental footprints because they consider the world outside of business.

And even in business, waste production is definitively inefficient.

Traceability, Visibility, and Transparency: “The Trifecta”

That these three “must-haves” are among our list of the top supply chain trends should come as no surprise. More and more, it is becoming clear to stakeholders, from trucking to freight to fulfillment and beyond, that visibility, transparency, and traceability are not just nice-to-haves. Instead, these days, it is not too hyperbolic to say the trifecta is a prerequisite for success in supply chain services.

But before we say any more, let’s define these terms in the context of these few paragraphs:

The term “visibility” refers to the use of data to obtain insight into how the supply chain is operating and to take actions to improve its efficiency. The idea is to observe every single ingredient/input, product, partner, handoff, and so on.

The term “visibility” refers to the use of data to obtain insight into how the supply chain is operating and to take actions to improve its efficiency. The idea is to observe every single ingredient/input, product, partner, handoff, and so on.

Transparency refers to sharing supply chain information internally and publicly so that all stakeholders, including consumers, can understand how you operate.

Traceability refers to tracking a product back to its source and establishing what it is and when it originated.

The last two years especially have demonstrated the need to optimize, safeguard, and leverage the supply chain for business value. And value is precisely what companies stand to gain when committed to traceability, visibility, and transparency with B2B partners, both in practice and as guiding principals.

The internet of things (IoT)

Here is one of those terms we all hear a ton but likely don’t fully understand. So here is a quick rundown:

IoT refers to a network of physical items connected to the internet by sensors and software. It’s how companies monitor their “integrated systems” and further reinforce visibility and flexibility for the entire supply chain.

If an issue emerges, such as a temperature excursion or a route diversion, IoT-enabled sensors placed with a shipment will provide a real-time alarm. As indicated, IoT plays a pivotal role in the food and beverage industry for the way it supports oversight of cold-chain and mitigates any risk to shipments. But in the era of COVID, IoT offers another wildly important application. Check out Rfxcel CEO Glenn Abood’s essay discussing real-time monitoring in the pharmaceutical cold chain. Rfxcel is a provider of supply chain track and trace solutions.